Efficient material management is essential for mining sites, construction zones, and logistics terminals where accurate measurement of bulk materials directly affects productivity and cost control. The integration of the benewake lidar distance sensor in these industries provides a reliable, automated solution for assessing material quantities in real time. Through advanced optical sensing, the technology ensures precise lidar stockpile measurement without the need for manual inspection or physical contact, improving both safety and efficiency.

Transforming Stockpile Monitoring with LiDAR Precision

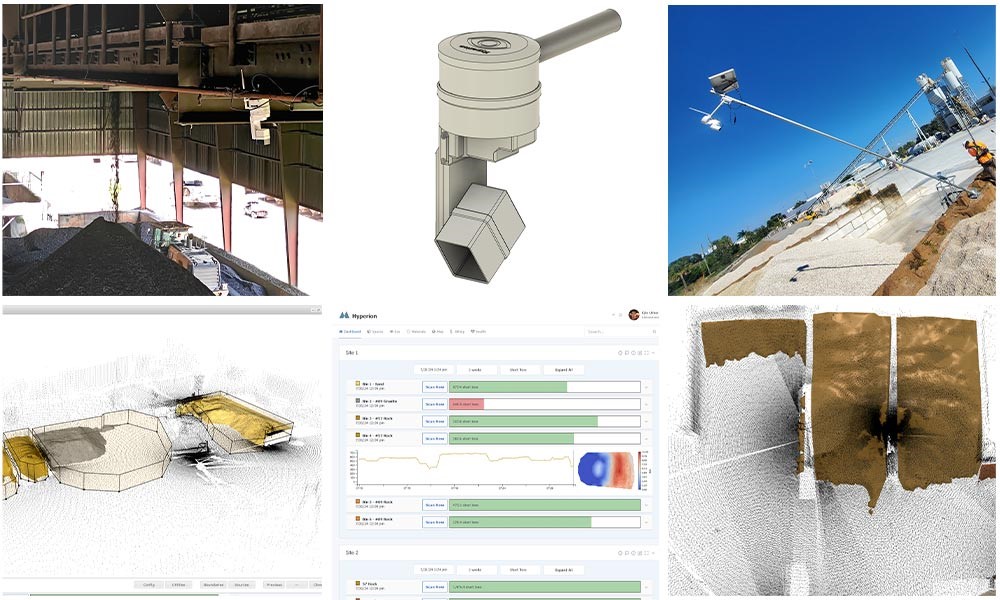

Benewake’s sensing solutions are specifically designed for fixed installations that require long-term stability and high data accuracy. When applied to lidar stockpile measurement, these sensors can continuously scan storage areas, producing 3D models that reflect real-time changes in material height and distribution. This automated process minimizes human error and reduces the need for frequent site visits. The Benewake LiDAR Volume Detection System operates effectively in dusty, low-light, or harsh industrial conditions, making it ideal for mines, cement plants, and cargo terminals where traditional measuring tools often struggle. Its advanced sensing capabilities allow accurate volume and distance measurements even in challenging environments, ensuring reliable performance for industrial applications.

Real-Time Insights for Smarter Inventory Decisions

Systems such as the Hyperion Real-Time Stockpile Measurement System, powered by the benewake lidar distance sensor and developed by Altamus Inc., demonstrate the potential of LiDAR in material tracking. The sensors continuously gather distance data, converting it into volume estimates that update instantly within digital management platforms. With lidar stockpile measurement, operators gain a clear overview of resource availability, enabling timely logistics decisions and better coordination of material flow. This approach reduces overstocking risks and streamlines operational planning across multiple industrial sectors.

Conclusion: Reliable Volume Detection for Industrial Applications

By utilizing benewake lidar distance sensor technology, industries can adopt a dependable, automated, and contact-free method for lidar stockpile measurement. The precision of LiDAR-based volume detection not only enhances efficiency but also supports sustainable material management by reducing waste and operational downtime. Through continued innovation and application in real-world environments, Benewake demonstrates its capability to redefine how enterprises monitor, record, and optimize bulk material inventories.